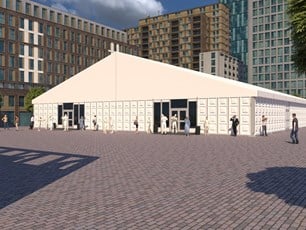

We create Space

Losberger De Boer delivers top class temporary and permanent space solutions for events, commercial, public, civil protection and defence use.

Contact LDB

Losberger De Boer solutions

Temporary and semi-permanent space solutions

Event Space

We are the inspirational partner that offers the complete package for the perfect event.

Our Event rental solutions

Commercial & Public Space

As a contractor, we help businesses meet their short term and long term space requirements.

Our Commercial solutions

Rapid Deployment Space

We are a global supplier of rapidly deployable shelters, emergency facilities and military space solutions.

Our Rapid Deployment solutionsLosberger De Boer solutions

A broad range of modular structures to meet your every need

Cases

We love to show you our work

Cases by Topic

‘Don’t tell me what you want – tell me what you want to achieve’

Barbara Kalksma

Barbara Kalksma, Senior Account Manager Events

‘It’s the complex challenges that really get our hearts pumping’

After almost 20 years with the company, events specialist Barbara Kalksma is still inspired and triggered by the projects Losberger De Boer do, and the challenges its clients present her with – every single day.

Quality of advice and materials

“I am proud to say that we can handle the most complex challenges. In fact: it’s the more challenging ones that really get our hearts pumping. That’s where we shine. The quality of our materials, advice and tailor made solutions, as well as our spotless delivery and installation make us an ideal partner for those seeking an event with a wow factor.”

Trust Barbara to do:

- Challenge and inspire you

- Add value to your event

- Give you a worry-free customer experience

About Losberger De Boer

Losberger De Boer is one of the world’s leading suppliers of temporary and permanent space solutions. Our structures and buildings are used for commercial purposes, public use, events, and military and humanitarian application.

Losberger De Boer was founded over 100 years ago, in 1919, in Heilbronn, Germany. The company is the result of the merger between Losberger and De Boer Structures. Losberger De Boer is headquartered in Fürfeld, Germany and has offices, production facilities and teams across the world. All Losberger De Boer buildings and tent structures are designed and produced inhouse. All our products are available for sale or rent/lease.

Losberger De Boer’s core value is embedded in the company slogan ‘Committed to your success’. We are dedicated to providing our clients with the best possible space solution and the best customer experience.