Navigating the UK's RAAC Crisis: What is RAAC, how will it impact your business and what can be done to prevent closing your doors?

If you have been impacted by the RAAC crisis and need urgent support, get in touch with our team at sales.uk@losbergerdeboer.com or give us a call directly at 01280 846500.

What is RAAC, how can it impact your business, and, most importantly, what can you do to prevent having to close your doors?

The start of the school year should have been a time of excitement and new beginnings. Still, more than 150 schools nationwide are now facing partial or complete closures, just days before the start of the new school year, over concerns related to Reinforced Autoclaved Aerated Concrete (RAAC).

RAAC (Reinforced Autoclaved Aerated Concrete)

RAAC stands for Reinforced Autoclaved Aerated Concrete – a lightweight building material widely used in the UK and other countries from the 1950s until the mid-1990s, which gained popularity for its lightweight nature, ease of installation, and affordability.

The structural integrity of RAAC was questioned back in 1994 when researchers raised concerns about its long-term durability. So, despite ceasing manufacturing in the UK during the 1980s, it continued to be utilized in construction projects worldwide.

Although RAAC was once a popular construction material due to its lightweight properties and good insulating capabilities, recent safety concerns and the revelation of its potential structural vulnerabilities have created a significant crisis for many buildings that have already integrated RAAC into their structures. As inspections, renovations, and replacements became essential, many businesses grappled with the immediate need for alternate spaces to continue operations.

How bad is the RAAC crisis?

RAAC use is not limited to schools; it has been used to build hospitals, airports, housing, theatres, and various other public buildings.

RAAC's inherent properties make it less durable than traditional concrete, with a lifespan of approximately 30 years. It is especially susceptible to sudden cracking, particularly in larger units, which can have catastrophic consequences, as we’ve seen. Additionally, RAAC's porous structure makes it vulnerable to moisture, chloride, and carbon dioxide, leading to corrosion of reinforcing agents within the concrete.

Where did concerns for RAAC come from?

There have been concerns about RAAC and its lifespan since its use. In the 1990s, it was believed that even time-expired RAAC posed no risk. Since then, in recent years, a primary school in Kent collapsed in 2018, calling for repeated warnings and calls for action from local councils and governments.

In 2021 and 2022, the Office of Government Property (OGP) sent out a formal warning notice about RAAC to stress that the material is now liable to collapse, highlighting how collapses had happened in schools with minimal or no warning at all.

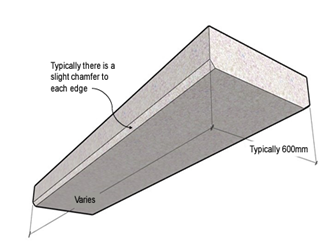

What do RAAC panels look like?

Source: Department for Education Reinforced Autoclaved Aerated Concrete (RAAC): Identification guidance, August 2023

Who is impacted by RAAC?

The full extent of the problem is still unknown; however, we do know that RAAC construction was used widely for all types of buildings, not just schools. So far, the OGP has identified 41 hospitals, all with RAAC-based construction, to add to the 150 schools at risk.

What is being done to resolve the RAAC crisis?

Following the directive to shut schools in August, the government collaborated with contractors and utility firms to expand temporary structures.

Chancellor Jeremy Hunt assured that the government is committed to investing whatever is necessary to ensure school safety.

So far, £1.8 billion in capital funding has been committed to ensure schools stay operational, and the School Rebuilding Programme has been launched, with plans to transform over 500 schools in the next ten years.

How can we help?

Losberger De Boer is at the forefront of the RAAC crisis, providing schools with fast, practical solutions to create safe temporary learning environments.

We can build you a new facility within weeks and deliver it turnkey, fully furnished with all your required facilities. Our structures can operate independently or connect seamlessly to existing buildings. Whatever the circumstances, we can provide a bespoke solution.

What can you expect from us?

- Initial Consultation: A discovery call, email or in-person meeting to discuss the needs of your project.

- Site Visit: We will visit you on-site to discuss your project in person and start working on the best solution for your requirements.

- Proposal: Proposal with drawings, 3D renders, concept images and all the details about exactly what we will provide and how much it will cost.

- Feedback & Adjustments: Once you have looked over your proposal, we will make any amendments if required before final designs and services are agreed upon.

- Planning: After choosing your perfect space solution, you can leave the rest to us, keeping you in the loop every step of the way.

- Delivery: After building, your structure will be delivered, turnkey, and ready for you to get back to business.

The Benefits of Semi-Permanent Structures

- Speed of Deployment: Semi-permanent structures can be erected quickly, often within days or weeks. This speed is critical during emergencies when immediate action is needed to provide students with a safe learning environment.

- Cost-Efficiency: Constructing traditional buildings for temporary use during emergencies or renovations can be expensive. Semi-permanent structures offer a cost-effective alternative, allowing educational institutions to redirect resources towards educational programs rather than construction expenses.

- Adaptability: These structures are highly adaptable, making them suitable for various purposes. Whether it's creating temporary classrooms, libraries, or administrative offices, semi-permanent structures can be customized to meet the specific needs of the educational institution.

- Sustainability: Many semi-permanent structures are designed with sustainability in mind. They can be made from eco-friendly materials and may be reused or repurposed, reducing the environmental impact of temporary facilities.

- Minimized Disruption: During renovations, semi-permanent structures allow the educational institution to continue operations without significant disruption. Students can stay on-site, maintaining a sense of continuity and stability.

- Longevity: While considered temporary, semi-permanent structures are built to last. They can continue being used for years, even after the crisis or renovation has passed.

Are your structures safe and compliant with building regulations?

Yes, we are a leading designer and manufacturer of demountable structures based on more than 100 years of experience.

- In-house design and R&D

- In-house manufacturing

- Structural calculations

- Quality inspection during manufacture

- Global engineering team

We have ISO 9001, 14001 and 45001 accreditations, meaning that we consistently provide products that meet customer standards, statutory and regulatory requirements.

We also hold a Construction Line Gold accreditation, meaning we go above and beyond PAS 91 requirements with enhanced quality management checks and Acclaim’s SSIP accreditation, which manages compliance and health & safety.

Case study: Lytchett Minster School – Rapid delivery of school building after a fire destroyed the entire school.

After a devastating fire at Lytchett Minster School, Losberger De Boer provided a complete and fully functional temporary school building ready for the students to return. This project had some specific requirements as the school specialises in performing arts.

Our project management team and build crew delivered 3300m2 of structure in just six weeks, meaning students could return to their timetable with minimal disruption.

This project required a collaborative effort from Losberger De Boer with the school's insurance company and loss adjusters from concept to contract.

Client Testimonial:

“I have been tremendously impressed by Losberger De Boer. They have been outstanding – not only in terms of the quality of their systems but also in how quickly they understood our project, both from a technical and educational perspective.”

– Stuart Clark, Headmaster at Lytchett Minster School.

Case study: The Gilberd School - Temporary dining facility required after RAAC was found in the school building.

Just days before the new school term was set to start, this school was told that they could no longer use parts of their building, which included their kitchen and dining facilities.

Our team arrived on site quickly and proceeded to build a temporary canteen/kitchen facility, which took just 2 weeks to complete.

Client Testimonial:

“The RAAC problem caused us to lose our kitchen and dining areas, so we had 1600 children thinking how are we gonna do this? Working with Losberger De Boer has been very easy. The actual build took less than 2 weeks and we are really pleased with the speed at which they’ve done it.

They’ve adapted to us, enhanced it in our school colours, been talking to us at all times, worked with our kitchen staff to ensure that the layout works for them, it has been really easy, incredibly professional and a pleasure really.”

- Nicola Elliott, Director of Finance and Operations

With over 100 years of experience under our belt, our rapid response in emergency situations remains a pillar of our business. You can leave the stress to us, knowing you are in a safe pair of hands.

To start discussing your needs, drop us an email or give us a call.

Email: sales.uk@losbergerdeboer.com

Phone: 01280 846500